Interested? Contact us now

In order to contact us please fill the form on the right or directly email us at the address below

sales@senecaesg.com

India, the world’s second-largest steel producer, faces the urgent challenge of decarbonizing its steel industry, a major contributor to carbon emissions. Currently, the country’s steel production relies heavily on the carbon-intensive Blast Furnace-Basic Oxygen Furnace (BF-BOF) method, which accounts for 43% of total output. This reliance, coupled with coal-based production, presents a significant environmental challenge. As India aims to produce 255 million tons of steel annually by 2030, the industry must adopt greener practices to avoid a surge in CO2 emissions.

Green steel technologies offer a promising solution. Methods like green hydrogen-based Direct Reduced Iron (H2-DRI) and scrap-based Electric Arc Furnaces (EAF) powered by renewable energy can reduce emissions by up to 97% and 88%, respectively, compared to traditional steelmaking processes. However, there is no universal definition for “green steel,” with different organizations setting varied emissions targets.

Despite the potential, India faces significant challenges in transitioning to green steel. The high initial capital investment for H2-DRI technology and the country’s limited steel scrap availability make it difficult to adopt EAF on a large scale. Additionally, the success of green steel hinges on integrating renewable energy sources into the steelmaking process.

To overcome these obstacles, India must implement a multi-pronged strategy. Policy support, such as mandating green steel production and offering tax incentives for decarbonization projects, is crucial. Expanding investments in renewable energy, including solar and wind, alongside the development of a national Carbon Capture, Utilization, and Storage (CCUS) strategy, can further accelerate the shift to carbon-neutral steel production.

By embracing these initiatives, India has the potential to lead the global green steel revolution, balancing economic growth with sustainability.

Sources:

https://www.teriin.org/sites/default/files/files/Achieving_Green_Steel_Roadmap.pdf

https://static.pib.gov.in/WriteReadData/specificdocs/documents/2024/may/doc2024510336301.pdf

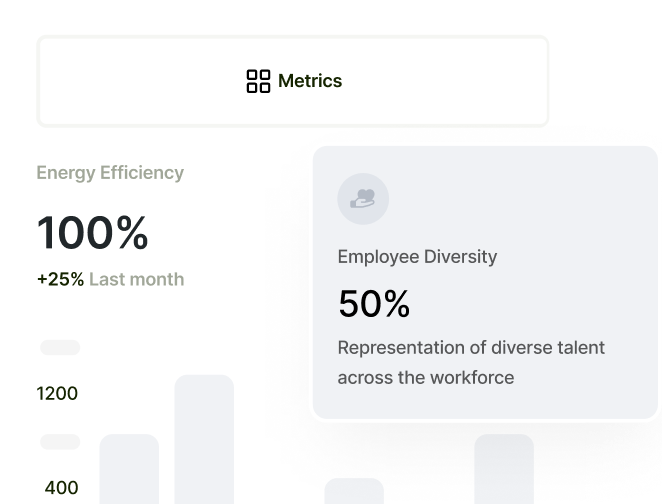

Monitor ESG performance in portfolios, create your own ESG frameworks, and make better informed business decisions.

In order to contact us please fill the form on the right or directly email us at the address below

sales@senecaesg.com7 Straits View, Marina One East Tower, #05-01, Singapore 018936

+(65) 6223 8888

Gustav Mahlerplein 2 Amsterdam, Netherlands 1082 MA

(+31) 6 4817 3634

77 Dunhua South Road, 7F Section 2, Da'an District Taipei City, Taiwan 106414

(+886) 02 2706 2108

Viet Tower 1, Thai Ha, Dong Da Hanoi, Vietnam 100000

(+84) 936 075 490

Av. Santo Toribio 143,

San Isidro, Lima, Peru, 15073

(+51) 951 722 377

1-4-20 Nishikicho, Tachikawa City, Tokyo 190-0022